Certified by the bureau of Indian standard under the code of IS 15351:2015

Technologically designed for UV resistance

Extra strong to provide added resistance to tears & punctures

On site installation with most advanced machinery

Largest width fabricated panels in Geo-membranes industry

Accepted and approved to all government subsidies

Geo-membrance comes with exclusive warranty for each specific defects

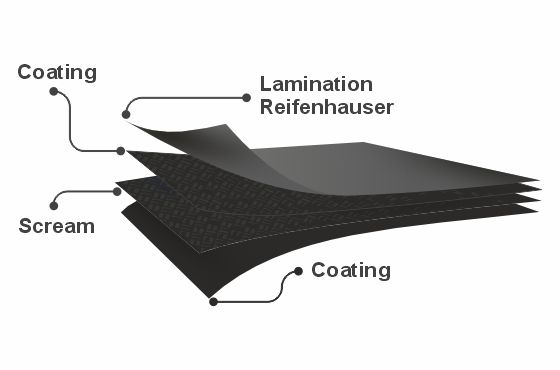

Engineered coatings provide exceptional hydrostatic resistance and heat seaming resistance

| Sr. No | TEST NAME | TEST METHOD | UMO | HIPPOSHIELD 300 | HIPPOSHIELD 500 | HIPPOSHIELD 750 | HIPPOSHIELD 1000 |

|---|---|---|---|---|---|---|---|

| 1 | Thickness | IS 7016 Part 1 | Micron | 300 | 500 | 750 | 1000 |

| 2 | Finished Weight | IS 7016 Part 1 | GSM | 250 | 420 | 650 | 950 |

| 3 | Carbon Black Content | IS 2530 | % | 2.5 | 2.5 | 2.5 | 2.5 |

| 4 | Breaking Strength on (20x10CM) before UV exposure | IS 13162 Part 5 | N | 3300 | 6600 | 8200 | 10700 |

| 5 | Elongation at Break on (20x10CM) before Uv exposure | IS 13162 Part 5 | % | 20±5 | 20±5 | 20±5 | 20±5 |

| 6 | Dart Impact test | Annex C, IS 15351:2015 | GSM | Pass | Pass | Pass | Pass |

| 7 | Tongue Tear Strength | IS 7016 Part 3 | N | 100 | 250 | 300 | 350 |

| 8 | Puncture Resistance | Annex D, IS 15351:2015 | N | 300 | 500 | 725 | 900 |

| 9 | Brushing Strength | IS 7016 Part 6 | N/CM | 60 | 110 | 135 | 200 |

| 10 | Seam strength before Uv exposure | IS 15060 | N/MM | 15 | 30 | 40 | 42 |

| 11 | Hydrostatic Resistance before UV exposuret | Annex E, IS 15351:2015 | KG/CM | No Leakage at 10kg/cm | No Leakage at 15kg/cm | No Leakage at 20kg/cm | No Leakage at 25kg/cm |

Scroll Right